Urban parking has become a critical issue in nearly every modern city. With land costs increasing and vehicle ownership rising, traditional garages and open lots cannot meet the demand. A shuttle parking system provides a highly efficient solution by integrating automation, advanced control technology, and modular design. It not only maximizes the use of available space but also delivers safe, fast, and user-friendly parking. This article XIZI iParking explores the system structure and workflow of shuttle parking systems.

Structural Components of a Shuttle Parking System

A shuttle parking system is a complex but highly efficient automated solution for parking vehicles in limited spaces. It consists of several critical components working in harmony to ensure smooth and precise operations. The following are the key structural elements that make up a typical shuttle parking system, each playing a unique role in maximizing efficiency, safety, and space utilization.

1. Entry and Exit Modules

The entry and exit modules serve as the first and last point of interaction for users with the shuttle parking system. These modules are typically fully enclosed bays where drivers park or retrieve their vehicles. Each module is equipped with a set of sensors and alignment guides to ensure that the vehicle is parked accurately within the system.

When a driver arrives at the entry bay, sensors detect the car’s size, weight, and position to ensure the vehicle is correctly aligned for the automated process to begin. This precise alignment prevents misplacement, ensuring that the shuttle system can accurately pick up and transport the car to the right storage location. At the exit module, a similar process occurs where the system retrieves the vehicle and delivers it to the driver with minimal wait time.

2. Vertical Lifts

Vertical lifts are crucial to the shuttle parking system as they move vehicles between different levels of the parking facility. These lifts act as elevators that raise or lower vehicles to their designated storage floor. Depending on the system’s size and capacity, multiple lifts can operate simultaneously, optimizing vertical space usage and reducing wait times for users.

The vertical lift system ensures that vehicles are stored efficiently across multiple floors, taking full advantage of the available space in multi-story parking structures. This also allows the shuttle parking system to handle large volumes of vehicles while maintaining smooth and continuous operation. The use of vertical lifts is one of the key factors that contribute to the system's ability to maximize parking density without the need for expansive land use.

3. Shuttle Carriers

Shuttle carriers are the heart of the shuttle parking system. These automated robotic platforms are responsible for transporting vehicles horizontally along rails between the vertical lifts and the parking racks. Shuttles can carry vehicles from the entry bay to the designated storage area or retrieve them for drivers when they request their cars.

The precision and speed of shuttle carriers are what make the shuttle parking system so efficient, even in large-scale parking facilities. Equipped with sensors and high-tech control systems, the shuttles navigate the rails with minimal clearance and precision, ensuring that cars are parked safely without any risk of damage. Their high-speed capabilities enable quick operations, allowing for short waiting times for users, even in systems with many vehicles.

4. Parking Racks

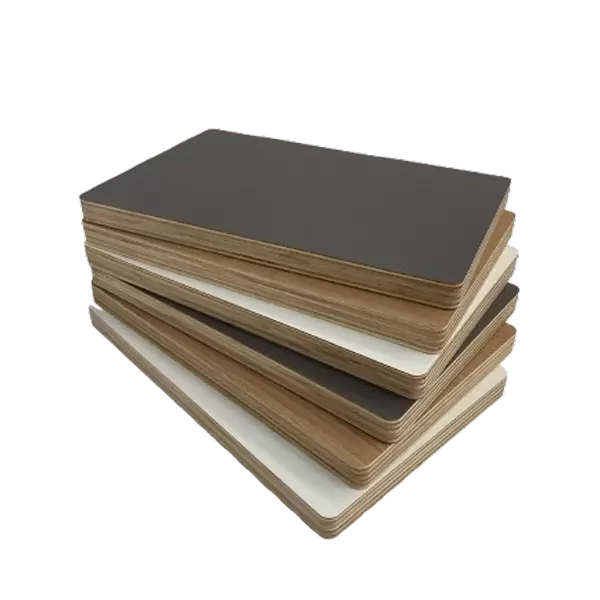

Parking racks are the structural slots where vehicles are stored once they have been transported by the shuttle carriers. These racks are typically made of steel or reinforced concrete and are designed to maximize the density of parked vehicles within the available space. The racks are carefully engineered to hold vehicles securely, with adjustable components to accommodate a wide range of car sizes.

In a shuttle parking system, parking racks are organized in a way that optimizes both horizontal and vertical space. The racks are designed to allow shuttles to park vehicles with minimal clearance, ensuring maximum utilization of available space. Additionally, these racks are designed to be durable, ensuring the long-term safety and stability of vehicles stored within the system.

5. Control and Monitoring System

The control and monitoring system is the brain of the shuttle parking system. This intelligent software platform coordinates the entire operation, managing the movement of lifts, shuttles, and vehicles. The control system assigns parking spots to incoming vehicles and optimizes the retrieval process, ensuring that vehicles are stored and retrieved in the most efficient way possible.

Using real-time data, the system tracks each vehicle’s location and monitors the operational status of each component. The software can dynamically adjust routes to minimize delays, prevent collisions, and ensure that vehicles are always parked in available spots. For users, the system provides a seamless and automated experience, while for operators, it offers real-time analytics and performance monitoring to ensure smooth, continuous operation.

6. Safety Systems

Safety is a paramount concern in any parking system, and a shuttle parking system incorporates several advanced safety features to protect both vehicles and users. Sensors are installed throughout the system to detect obstacles or malfunctions, preventing accidents or damage. If any issues are detected, the control system will alert operators or automatically halt the system to prevent further complications.

In addition to these sensors, the shuttle parking system includes cameras and monitoring devices to provide security surveillance for the entire facility. This helps ensure that only authorized users have access to the parking area and minimizes the risk of theft or vandalism. Fire protection systems are also integrated into the design to ensure the facility remains safe in case of an emergency. The automated nature of the shuttle parking system reduces the need for human interaction, further enhancing safety by limiting the potential for accidents inside the facility.

Operational Workflow of a Shuttle Parking System

The operational workflow of a shuttle parking system is highly automated and efficient. While the process may appear straightforward to users, it involves precise coordination between various components to ensure smooth operation. Here is a step-by-step overview of how a typical shuttle parking system works:

Vehicle Check-In

The process begins when the driver arrives at the entry bay. After parking, sensors detect the car’s dimensions, weight, and positioning. The system checks that the vehicle is correctly aligned with the shuttle and ready for transport. Once confirmed, the vehicle is automatically handed over to the system.

This step is key to ensuring that the vehicle is parked in the correct position, eliminating the need for the driver to maneuver into individual parking slots. The user simply parks and leaves, and the system takes over from there.

Transfer to Storage Level

Once the vehicle is in position, a vertical lift is activated to raise or lower the vehicle to the appropriate storage level. The control system assigns an optimal parking slot based on availability and the most efficient route for retrieval. This ensures that the system is always optimized for maximum capacity and minimum waiting time.

The vertical lift handles the heavy lifting, while the shuttle system coordinates the horizontal transport of vehicles, ensuring seamless storage and retrieval.

Shuttle Movement

Once the vehicle has been transferred to the appropriate level, the shuttle carrier picks it up and moves it horizontally along the rails to the allocated parking slot. The shuttle carrier is designed to carry the vehicle safely and securely, even in tight spaces, ensuring that no damage occurs during transport.

With high-speed, high-precision movement, the shuttle carrier can quickly and efficiently move the vehicle into its designated rack, making the shuttle parking system a fast and reliable parking solution.

Storage

Once the shuttle has transported the vehicle to the designated parking rack, it carefully positions the car into the slot with minimal clearance. The system logs the slot location in real time, allowing for easy tracking and retrieval.

This efficient use of space ensures that vehicles are stored compactly while still allowing for easy access and retrieval when needed.

Retrieval

When the driver returns and requests their car, the process is reversed. The shuttle retrieves the vehicle from its storage slot and transports it back to the lift. The lift then lowers or raises the car to the exit bay, where the driver can retrieve it. The entire retrieval process is quick, usually taking just a few minutes.

This automated, seamless workflow makes shuttle parking systems a fast and convenient option for drivers, while maximizing space and minimizing wait times.

The shuttle parking system is a sophisticated, automated solution that significantly improves parking efficiency and space utilization. With its precise structural components, seamless operational workflow, and numerous safety features, it provides a convenient, secure, and environmentally friendly parking solution for both urban and commercial areas. As cities continue to grow and space becomes more limited, the shuttle parking system offers a scalable, flexible, and highly efficient solution for meeting the increasing demand for parking. By embracing this innovative technology, both parking facility operators and users can enjoy a more streamlined, convenient, and sustainable parking experience.

www.xizipark.com

HANGZHOU XIZI IPARKING CO., LTD.

Average Rating