As industries grow and environmental regulations tighten, the need for efficient and sustainable waste treatment technologies has never been greater. Among the most effective solutions for hazardous and complex waste materials is the waste rotary kiln—a high-performance incineration system widely used for treating solid, liquid, and gaseous waste.

But what exactly is a waste rotary kiln, how does it work, and why is it so important in modern waste management? Let’s dive in.

What Is a Waste Rotary Kiln?

A waste rotary kiln is a type of incinerator used primarily for high-temperature thermal treatment of various waste materials. The kiln is a cylindrical, slightly inclined rotating vessel that continuously moves waste through a heated chamber, breaking down hazardous substances through controlled combustion.

It’s commonly used to treat solid waste, chemical residues, medical waste, and even volatile organic compounds (VOCs). Thanks to its continuous operation and high-temperature environment, a rotary kiln ensures complete combustion, reduced emissions, and safe disposal of harmful substances.

How Does a Waste Rotary Kiln Work?

The rotary kiln operates in several stages:

-

Waste Feeding

Waste materials are introduced into the upper end of the rotary kiln. These can include solids, sludges, or liquids, depending on the design. -

Rotation and Movement

The slow rotation of the kiln moves the waste gradually along its length, ensuring even exposure to heat and mixing. -

Thermal Decomposition

As the waste moves through the kiln, it is subjected to temperatures between 800°C and 1200°C. This process breaks down organic materials and neutralizes harmful substances. -

Combustion and Gas Treatment

The byproduct gases pass through a secondary combustion chamber or afterburner, where they are further oxidized. Cleaned gases are then passed through filters and scrubbers before being released into the atmosphere. -

Ash Removal

Inert residues or ash are collected at the discharge end of the kiln for safe handling or disposal.

Key Benefits of Waste Rotary Kilns

1. High Thermal Efficiency

Rotary kilns maintain stable high temperatures, ensuring complete destruction of organic waste and dangerous compounds.

2. Versatility

They can handle a wide range of waste types—solid, liquid, slurry, or gas—making them suitable for complex waste streams.

3. Continuous Operation

Unlike batch systems, rotary kilns can operate continuously, which enhances productivity and reduces downtime.

4. Environmental Compliance

Advanced pollution control systems integrated with rotary kilns ensure emissions meet or exceed environmental standards.

5. Heat Recovery Options

Rotary kilns can be equipped with heat recovery systems to generate steam or electricity from waste combustion, improving overall energy efficiency.

Applications Across Industries

Waste rotary kilns are widely used in industries such as:

-

Chemical and petrochemical manufacturing

-

Pharmaceutical waste disposal

-

Hazardous waste treatment

-

Medical and hospital waste management

-

Municipal waste incineration

-

Paint, resin, and coating industries

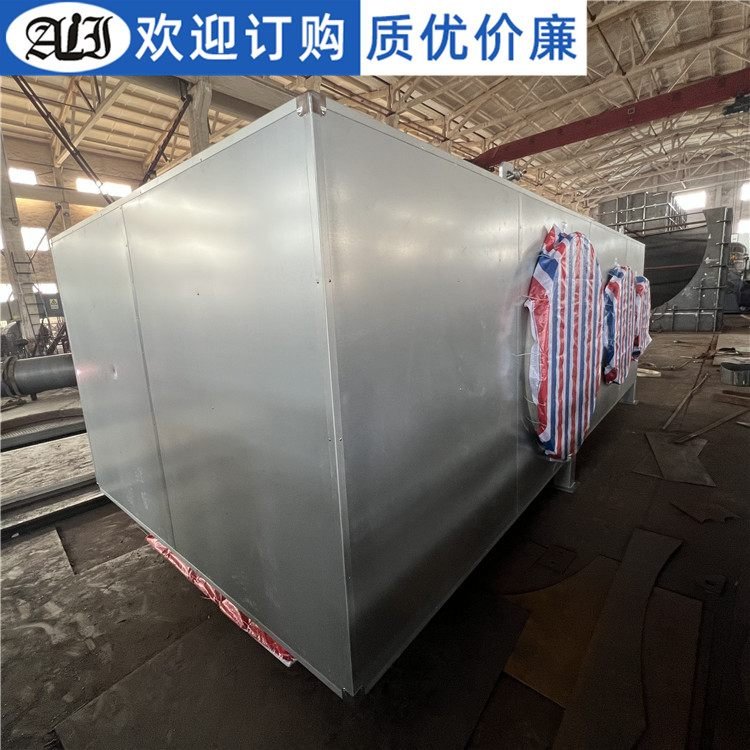

Airali Environmental Protection Technology: Leading the Way in Waste Incineration Solutions

When it comes to designing and building reliable waste rotary kilns, Airali Environmental Protection Technology is a recognized leader in the field. As a high-tech environmental enterprise, Airali specializes in the design, production, installation, commissioning, and turnkey contracting of pollution control equipment.

The company focuses on integrated waste treatment systems, particularly for organic waste gas, organic liquid waste, and hazardous waste—areas where rotary kilns play a vital role. Airali’s product range includes:

-

Solid waste incinerators

-

Medical waste pyrolysis furnaces

-

Rotary kiln incinerators

-

Thermal oxidation units for organic gases

-

RTOs (Regenerative Thermal Oxidizers)

-

Catalytic incinerators

-

Liquid waste incineration systems

-

Heat recovery equipment

By integrating cutting-edge technologies and adhering to strict environmental standards, Airali delivers safe, efficient, and sustainable waste treatment solutions tailored to client needs across China and beyond.

Final Thoughts

The waste rotary kiln stands out as a versatile and powerful solution for hazardous and industrial waste treatment. Whether it's neutralizing toxic compounds, recovering heat energy, or ensuring regulatory compliance, this technology plays a crucial role in modern environmental protection strategies.

For businesses seeking a trusted partner in waste treatment and incineration systems, Airali Environmental Protection Technology offers end-to-end solutions backed by technical expertise and years of industry experience.

If you're exploring a waste treatment project or want to learn more about rotary kiln systems, Airali is ready to support you with innovative, reliable, and green solutions.

www.wxallhb.com

Wuxi Ailali Environmental Protection Technology Co., Ltd.

Average Rating