The automotive industry has evolved into a highly automated, precision-driven ecosystem where efficiency, safety, and customization determine success. Among the many innovations supporting this evolution, the automotive rear suspension rack stands out as a critical logistics and handling solution that optimizes storage, transport, and assembly processes in vehicle production lines. In this blog post, DOPRO, a high quality warehouse steel storage racks manufacturer, will share the design principles of custom automotive rear suspension rack for sale, etc.

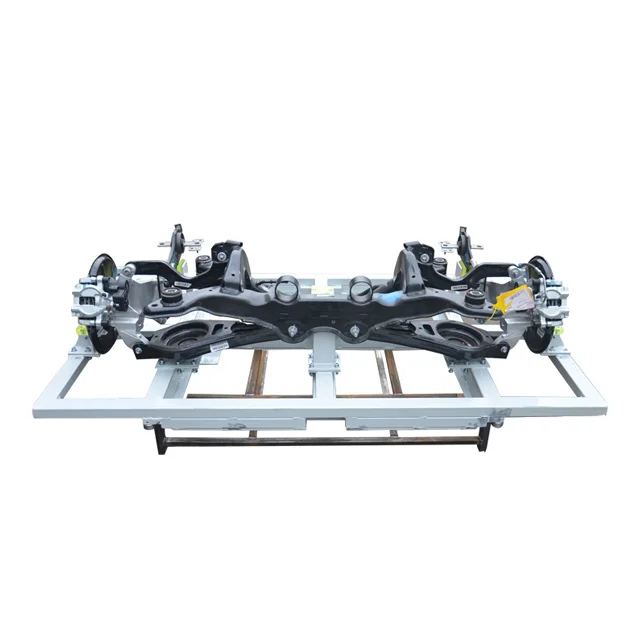

Steel-Structured Custom Rear Suspension Rack for Stability and Strength

A custom automotive rear suspension rack is not merely a storage frame—it is a structural solution engineered to support the weight and shape of complex suspension components. Constructed entirely from high-quality steel, the rack ensures exceptional stability and long-term durability.

The steel framework provides:

-

High load-bearing capacity, enabling the secure transport of heavy suspension assemblies.

-

Superior impact resistance, crucial for factory environments with frequent material handling.

-

Structural integrity, maintaining form and precision even under continuous operational stress.

In manufacturing settings, such as Great Wall Motor’s Tianjin factory, steel-structured racks are relied upon for both production and logistics efficiency. Their rigid construction prevents deformation, ensuring each component remains in position and reducing the risk of production delays due to misalignment or damage.

Polyurethane Cushioning for Safe Component Protection

Beyond strength, a customized automotive suspension storage rack must also protect delicate components from damage during handling. Inside each rack, polyurethane (PU) inlay cushioning materials are strategically installed.

Polyurethane offers multiple benefits:

-

High toughness and abrasion resistance, ensuring long service life.

-

Shock absorption, preventing collision damage when parts are loaded or transported.

-

Surface protection, safeguarding painted or coated components from scratches.

By integrating polyurethane inserts, manufacturers minimize costly component rework and extend part lifespan. This cushioning design reflects a broader trend toward intelligent material handling systems, where safety and precision coexist.

Foldable Rear Suspension Racks for Space Optimization

Storage space is one of the most valuable assets in any automotive manufacturing facility. The foldable rear suspension rack addresses this challenge through its special stacking foot design, allowing multiple racks to be stacked vertically or folded when empty.

This innovation provides several key advantages:

-

Space-saving efficiency, particularly in automated warehouses.

-

Ease of handling, with quick folding mechanisms for rapid deployment.

-

Improved storage density, maximizing the use of floor and vertical space.

When integrated into automated three-dimensional warehouses (AS/RS) or automatic packaging systems, foldable racks streamline logistics operations and reduce downtime. The combination of structural rigidity and collapsible design allows seamless movement between production, storage, and transport zones.

Adaptability for Automated Logistics and Smart Warehouses

Modern vehicle assembly lines rely heavily on automation and digital warehousing to maintain production continuity. The custom automotive suspension rack is specifically designed to integrate with automated storage and retrieval systems (AS/RS), robotic handling units, and smart conveyors.

These systems benefit from racks that are:

-

Precision-engineered for robotic compatibility, with standardized pickup points.

-

Dimensionally accurate, ensuring seamless transitions between stations.

-

Durable under repetitive automated movement, maintaining alignment even after thousands of cycles.

Such adaptability supports lean manufacturing principles, where efficiency and accuracy replace manual intervention. The result is a smoother, safer, and more predictable material flow from sub-assembly to final installation.

Customized Design for Diverse Automotive Applications

Every automaker has unique engineering requirements, which is why non-standard suspension racks have become indispensable in the industry. DOPRO’s custom design services allow manufacturers to tailor each rack according to specific vehicle models and production conditions.

Customization options include:

-

Material selection, ensuring compatibility with various operational environments.

-

Dimensional flexibility, adapting to the size and geometry of rear suspension assemblies.

-

Color coding, aiding visual management and inventory tracking.

-

Integration with domestic and foreign gearbox systems, ensuring cross-model versatility.

This flexibility allows OEMs and suppliers to maintain consistent standards across production facilities worldwide, improving interchangeability and reducing logistic complexity.

Industrial Collaboration: Proven Performance in Automotive Manufacturing

The collaborative success between DOPRO and Great Wall Motor’s Tianjin factory highlights how tailored engineering can elevate automotive logistics. DOPRO’s custom suspension racks have been specifically configured to fit Great Wall’s production layout, facilitating efficient loading, unloading, and automated handling.

These custom solutions demonstrate the importance of engineering partnerships in advancing industrial productivity. By aligning rack design with production needs, manufacturers can minimize equipment downtime, reduce manual labor, and maintain consistent component quality.

Sustainable and Long-Term Manufacturing Benefits

While the primary goal of a custom automotive rear suspension rack is operational efficiency, its long-term sustainability benefits are equally significant. High-strength steel structures ensure extended service life, while polyurethane inserts reduce part waste. Additionally, the foldable design lowers storage footprint, contributing to energy-efficient logistics operations.

Over time, these improvements translate to measurable cost reductions, better resource allocation, and a smaller environmental footprint—aligning with the automotive sector’s push toward sustainable manufacturing ecosystems.

Future of Custom Suspension Rack Design

As automotive technologies continue to evolve, so too will the design of custom suspension handling systems. Future developments may include:

-

Smart tracking features, integrating RFID or QR systems for real-time logistics visibility.

-

Lightweight composite materials, combining strength and portability.

-

Modular construction, enabling fast reconfiguration for different car models.

The shift toward electric vehicles (EVs) and autonomous manufacturing will further expand the role of custom suspension racks as adaptable, intelligent tools within connected factories.

Conclusion

The custom automotive rear suspension rack is far more than a steel frame—it is a precision-engineered logistics solution designed to meet the demands of modern vehicle manufacturing. With its robust steel structure, protective polyurethane inlays, foldable design, and compatibility with automated systems, it plays a central role in achieving safe, efficient, and sustainable production.

Through continuous innovation and collaboration, brands like DOPRO are redefining what industrial customization means for the automotive industry—bridging the gap between mechanical engineering excellence and smart manufacturing efficiency.

www.cndopro.com

DOPRO

Average Rating