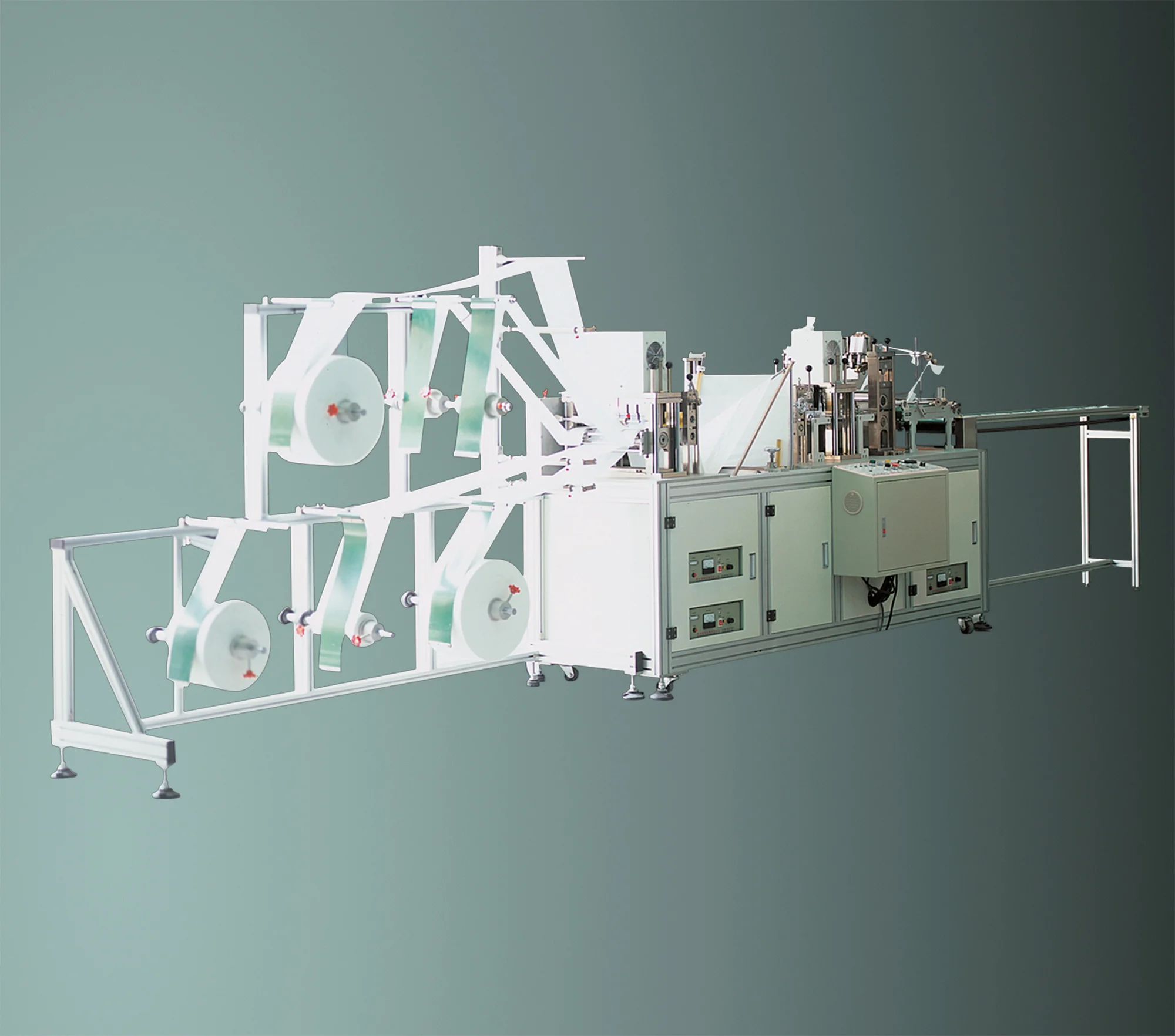

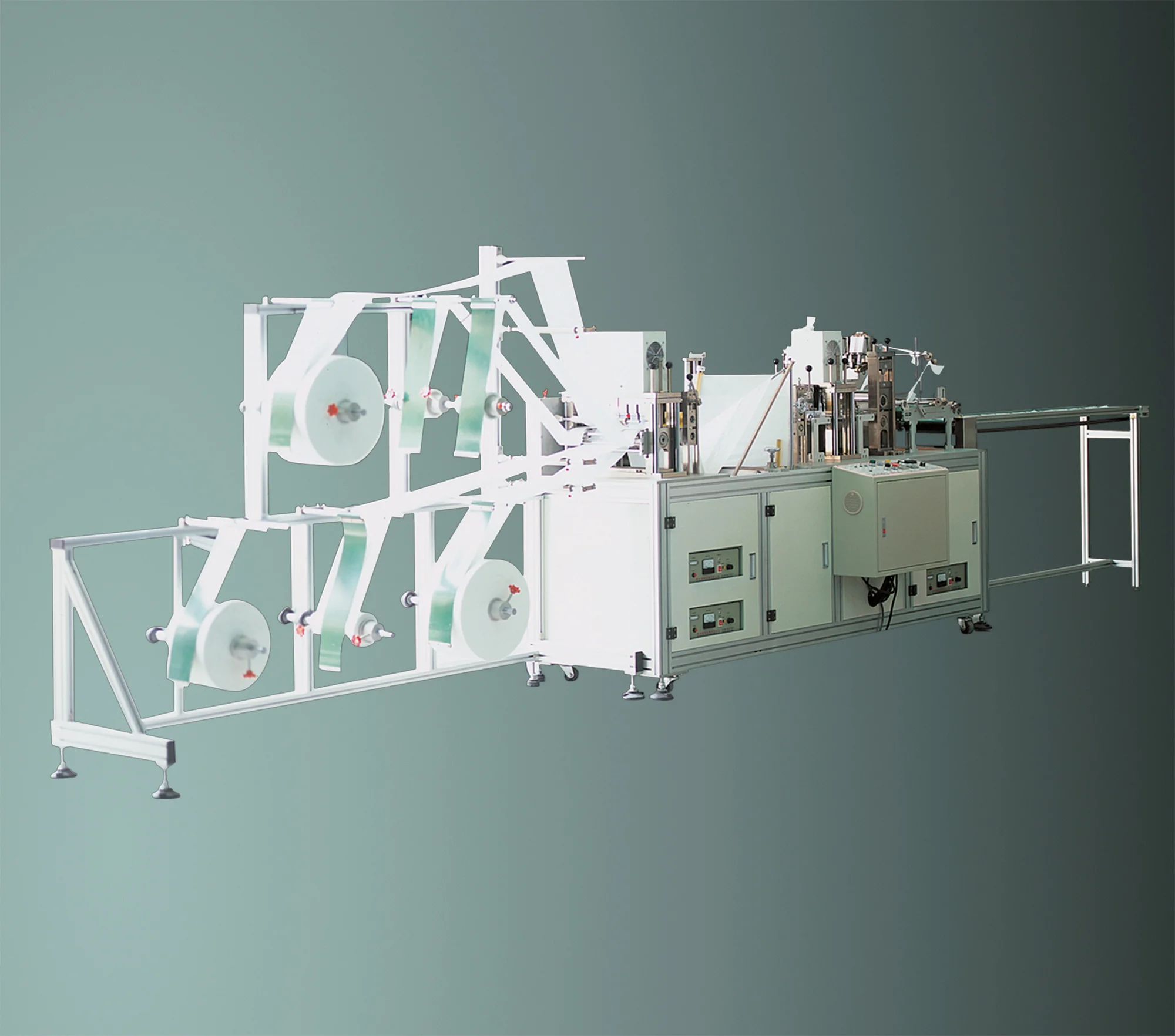

As global demand for personal protective equipment continues to evolve, solid face mask making machines have become essential for manufacturers aiming to produce high-quality, efficient, and comfortable masks at scale. These advanced machines combine precision engineering, automation, and innovation to meet rigorous standards for safety and hygiene. In this guide, we’ll explore the core functions, applications, and benefits of solid face mask making machines, and highlight how Broadfair Automation Equipment Co., Ltd. has become a trusted name in this field.

Understanding Solid Face Mask Making Machines

A solid face mask making machine is a fully automated system designed to produce non-woven face masks used in medical, industrial, and personal settings. Unlike semi-automatic systems, these machines streamline the entire process—from feeding and folding materials to ultrasonic welding, cutting, and ear loop attachment. The result is a finished mask with consistent quality and strong bonding performance.

The design of these machines emphasizes precision and speed, ensuring high output without compromising on mask comfort or filtration efficiency. Whether used for disposable surgical masks or high-protection respirators, solid mask making machines are built to maintain stringent production standards.

Key Functions and Features

Solid face mask making machines integrate multiple stages of mask production into one seamless workflow. Key functions typically include:

Automatic Material Feeding: The system accurately feeds multiple layers of non-woven fabric and melt-blown material, ensuring correct alignment and consistent mask thickness.

Folding and Forming: The machine folds the fabric layers to shape the mask body, maintaining a stable structure suitable for various mask types.

Ultrasonic Welding: High-frequency ultrasonic technology bonds layers securely without the need for adhesives, enhancing both durability and hygiene.

Ear Loop or Strap Welding: Automatic welding mechanisms attach ear loops or straps precisely, improving efficiency and ergonomic fit.

Cutting and Stacking: Finished masks are automatically cut, counted, and stacked for packaging, minimizing manual handling and contamination risk.

These functions are often enhanced with PLC control systems, touchscreen interfaces, and fault detection sensors for easy operation and maintenance.

Broadfair Automation Equipment Co., Ltd.: A Leader in Mask Machine Innovation

Broadfair Automation Equipment Co., Ltd. is a high-tech enterprise integrating R&D, manufacturing, and sales of advanced automation equipment. With a strong focus on innovation and precision engineering, Broadfair has developed a comprehensive range of mask production machinery that meets the growing needs of global healthcare and industrial sectors.

The company’s solid face mask making machines stand out for their high-speed performance, stability, and intelligent control systems. Broadfair’s commitment to continuous improvement ensures that their equipment not only meets international quality standards but also adapts to diverse mask designs and materials. Their professional R&D team works closely with clients to deliver customized automation solutions that enhance productivity and reliability.

Applications Across Industries

Solid face mask making machines serve a broad spectrum of industries and environments. Common applications include:

Medical and Healthcare Facilities: Production of surgical and medical-grade masks to ensure safety in hospitals and clinics.

Industrial Protection: Manufacturing dust-proof and anti-pollution masks for construction, manufacturing, and mining sectors.

Consumer and Retail Markets: Producing stylish and comfortable daily-use masks that blend safety with fashion.

Public Health and Emergency Supply: Supporting government and humanitarian initiatives for large-scale protective equipment distribution.

As global awareness of hygiene and environmental health grows, demand for automated mask production lines is expected to remain strong. Solid mask making machines play a vital role in meeting these demands efficiently and sustainably.

Benefits of Investing in Advanced Mask Production Equipment

Manufacturers who invest in solid face mask making machines gain significant advantages:

Higher Production Efficiency: Fully automated systems reduce labor costs and increase output rates.

Consistent Quality Control: Precision engineering ensures every mask meets required specifications.

Reduced Waste: Optimized material usage helps lower production costs and environmental impact.

Adaptability: Machines can be customized for different mask designs and specifications.

Improved Safety: Automation minimizes human contact, reducing contamination risks.

Conclusion

In today’s fast-paced manufacturing environment, solid face mask making machines represent the future of efficient, reliable, and scalable mask production. By combining intelligent automation, advanced control systems, and superior design, these machines empower manufacturers to meet global demand with confidence.

With its expertise in research, development, and innovation, Broadfair Automation Equipment Co., Ltd. stands at the forefront of this industry—delivering cutting-edge solutions that redefine productivity and quality in mask manufacturing. For businesses seeking dependable technology and comprehensive support, Broadfair is a partner dedicated to driving success in the modern era of automated production.

From Design to Production: A Step-by-Step Guide to Using Solid Face Mask Making Machines

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.

Average Rating