In today's digital age, printing remains an essential aspect of various industries. Whether you're a business owner, a designer, or an individual looking to print personal documents, choosing the right printing method is crucial. With a plethora of options available, it can be overwhelming to determine which type is best suited for your specific needs. In this comprehensive guide, we will explore different printing methods and help you make an informed decision. So, let's delve into the world of printing and discover what type is best to print.

- Offset Printing:

Offset printing, also known as lithography, is a widely used method for high-quality, large-scale printing. It involves transferring ink from a plate to a rubber blanket and then onto the printing surface. This technique is ideal for projects that require precise color reproduction and sharp details. Offset printing is commonly used for brochures, magazines, and packaging materials. - Digital Printing:

Digital printing has revolutionized the printing industry with its speed, flexibility, and cost-effectiveness. This method involves directly transferring digital files onto various substrates, eliminating the need for printing plates. Digital printing is suitable for short print runs, personalized materials, and quick turnaround times. It offers vibrant colors and allows for variable data printing, making it ideal for business cards, flyers, and promotional materials. - Screen Printing:

Screen printing, also known as silk screening, is a versatile method that involves pushing ink through a mesh screen onto the printing surface. This technique is commonly used for printing on textiles, such as t-shirts, hoodies, and banners. Screen printing offers durability, vibrant colors, and the ability to print on various materials. It is an excellent choice for custom apparel, promotional items, and artistic prints. - Flexography:

Flexography is a printing method primarily used for packaging materials, labels, and corrugated boxes. It utilizes flexible relief plates and fast-drying inks to transfer images onto substrates. Flexography is known for its high-speed production capabilities, excellent print quality, and suitability for printing on uneven surfaces. It is commonly used in the food and beverage industry, where packaging requires vibrant graphics and product information. - 3D Printing:

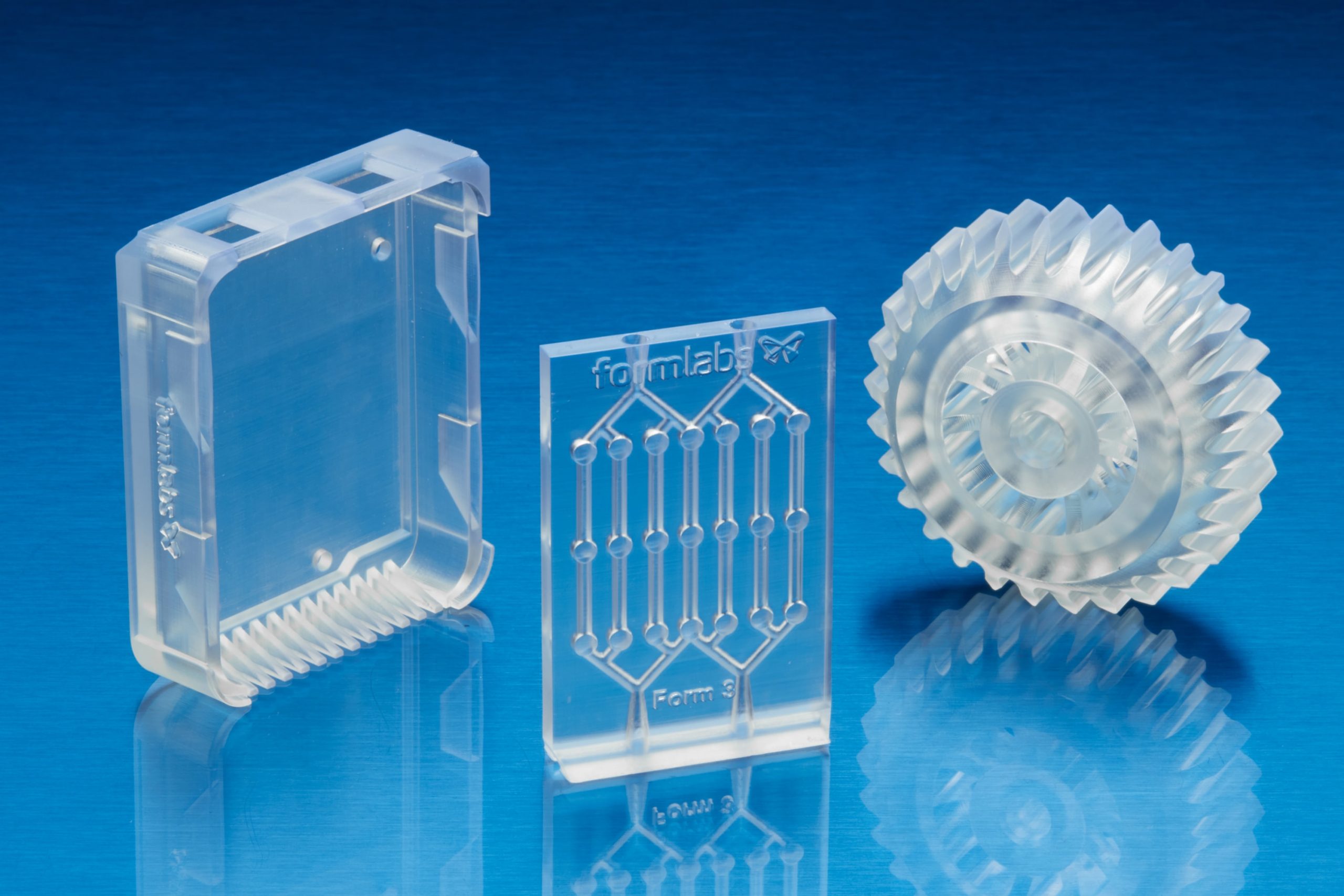

In recent years, 3D printing has emerged as a groundbreaking technology with applications across multiple industries. This additive manufacturing process creates three-dimensional objects by layering materials based on digital designs. 3D printing allows for intricate designs, rapid prototyping, and customization. It finds applications in fields such as product development, healthcare, architecture, and automotive manufacturing.

Conclusion:

Choosing the best printing method depends on various factors, including the nature of your project, desired print quality, budget, and turnaround time. Offset printing offers exceptional quality for large-scale projects, while digital printing provides flexibility and speed for smaller runs. Screen printing is ideal for custom apparel, and flexography excels in packaging materials. Additionally, 3D printing opens up new possibilities for complex and customized objects. By understanding the strengths and applications of each printing method, you can make an informed decision and achieve the best results for your specific needs.

Average Rating